PCB Router: A powerful assistant in electronic manufacturing industry

With the rapid development of the electronics manufacturing industry, the depanel machine, as an efficient and precise processing equipment, has gradually become an important role in the production line. Panel splitting machines , also known as cutting machines or cutting machines, are mainly used to quickly and accurately cut large circuit boards, panels and other materials according to preset sizes and shapes. It not only improves production efficiency, but also greatly reduces operating difficulty and labor costs.

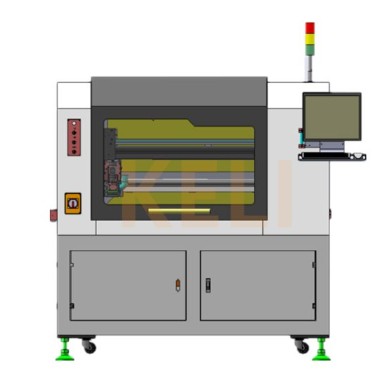

1. Structure and working principle of the depanel machine

The depaneling machine usually consists of a workbench, cutting tool, control system and other parts. The workbench is responsible for fixing the material to be processed to ensure its stability; the cutting tool is responsible for cutting according to the preset path; the control system is the "brain" of the entire equipment, responsible for issuing instructions and controlling the movement trajectory and speed of the tool.

2. Application fields of depanel machine

Depaneling machines are widely used in many fields such as electronic manufacturing, printing and packaging, and building materials. In the electronics manufacturing industry, deboarding machines are used to produce various circuit boards, display screens, touch screens and other key components. Its precise cutting capabilities ensure product quality and performance.

3. Advantages and characteristics of depaneling machine

High efficiency: The plate router adopts advanced cutting technology and can complete a large number of cutting tasks in a short time, significantly improving production efficiency.

High precision: Through precise control systems and high-quality cutting tools, the depaneling machine can achieve micron-level cutting accuracy to meet high-precision processing needs.

Easy to operate: The control system of the depanel machine usually adopts touch screen operation, with a friendly interface and easy to use.

Safe and reliable: The equipment design takes into account safety factors, such as emergency stop buttons, protective covers, etc., to ensure the safety of operators.

4. Development trends of depaneling machines

With the advancement of technology, depaneling machines are constantly being upgraded and improved. In the future, depaneling machines will be more intelligent and able to achieve more complex cutting paths and higher processing accuracy. At the same time, with the improvement of environmental awareness, depaneling machines will also pay more attention to energy conservation and emission reduction, and promote green manufacturing.

5. Summary

As one of the important equipment in the electronics manufacturing industry, the depanel machine brings great convenience to production with its characteristics of efficiency, accuracy and safety. As technology continues to advance, depanelers will continue to play a key role in the electronics manufacturing industry and promote the rapid development of the entire industry.