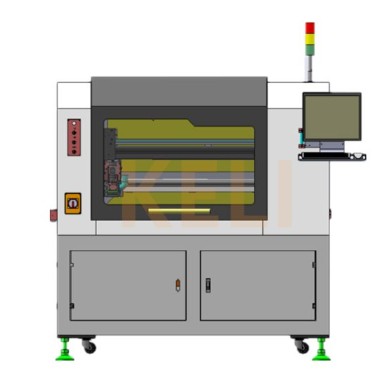

KELI Automation's high-performance PCB router brings about a new revolution in the field of circuit board splitting

With the rapid development of science and technology, automation equipment is increasingly used in all walks of life. As an indispensable part of electronic manufacturing, the performance of the PCB router directly affects production efficiency and product quality. KELI Automation has launched a high-performance PCB router.

This KELI Automation PCB router adopts advanced MARK point automatic correction technology to ensure the stability of cutting. Whether in continuous production or intermittent production, this technology can effectively ensure the cutting accuracy and improve production efficiency.

It is worth mentioning that the panel router also has an optional barcode scanning function, through which users can quickly and accurately identify and change programs, greatly improving the convenience of operation. At the same time, this function also supports automatic program changes, further reducing manual intervention and improving production efficiency.

In addition, the board router of KELI Automation also has a cutting path optimization function. This function can modify and offset the cutting path as a whole, making the cutting process more flexible and efficient. At the same time, the equipment also has a tool life monitoring function, which can monitor the use of the tool in real time and remind you to replace the tool in time, ensuring the continuity and stability of production.

In terms of stability and accuracy, this depaneling machine demonstrates extremely high performance. Its self-diagnosis function can quickly identify and solve potential problems, reducing the failure rate and improving the stability of the equipment.

As a company focusing on the research and development and production of automation equipment, KELI Automation has always been committed to providing customers with high-performance and high-stability products. The board router launched this time not only has powerful functions, but also makes a commitment in after-sales service. KELI Automation implements a maintenance and lifetime warranty policy for its products to ensure that customers can get troubleshooting and technical support in a short time.

In addition, KELI Automation has an experienced and technology-first production team, mature processes and sophisticated process processing capabilities, which further ensure the stability of the equipment and the forward-looking nature of the products. This makes KELI Automation's board routers highly competitive in the market and are deeply favored by customers.

It is worth mentioning that this depaneling machine also supports dual-spindle application and broken tool detection function. The dual-spindle application enables the equipment to handle more tasks at the same time, improving production efficiency; while the broken tool detection function effectively reduces production accidents caused by tool breakage, further ensuring the stability and safety of production.